Humidification & humidity control in pharmaceutical manufacturing

Many processes in pharmaceutical manufacturing require tight control over humidity. Tablet coatings with aqueous solutions need precise humidity to ensure the coating does not dry too fast or too slowly.

Printing with water based inks can be adversely affected by dry air. Low humidity causes an increase in static, which in turn can cause materials to stick to each other causing problems with packing.

Being able to consistently and reliably control humidity levels in pharmaceutical manufacturing, no matter what the ambient air conditions are, leads to a more efficient production line, increased yields and decreased waste.

Condair offers systems capable of controling humidity levels with utmost precision and the specialist accessories, such as sensors and distribution pipes, needed to control and deliver the humidity. These products are combined with the design knowledge Condair has from extensive experience in the sector, to ensure the humidity control system delivers the exact conditions required by a pharmaceutical manufacturing process.

As pharmaceutical facilities often need 24/7 environmental control, it’s important that the humidity control system is designed specifically for the application. Standard heating, ventilating and air conditioning systems can rarely deliver the optimum conditions required.

By working alongside the client’s research and development team, Condair has managed to increase production yields in some pharmaceutical manufacturing environments by as much as 60%. Through testing production at different humidities and then holding optimum levels indefinitely during manufacturing, wastage due to poor environmental control can be significantly reduced.

Get free advice from an expert in pharmaceutical humidity control

Benefits of Condair humidification in the pharmaceutical industry include:

- Extensive expertise around the world with many pharmaceutical applications

- Increased production efficiency, higher yields and reduced waste

- Comprehensive product range to precisely meet customers' requirements

- Ability to provide innovative custom solutions for unusual processes

- Low energy systems to reduce operating costs and improve humidity control

- Low maintenance solutions to reduce on-going service requirements

- Comprehensive service of expert advice, design, supply, installation, commissioning, maintenance and spares supply

- Johnson & Johnson, UK

- Sun Pharmaceuticals Ltd, India

- Teva, Eire, Netherlands & Russia

- Hollister, Eire

- GlaxoSmithKline, UK

- Productos Roche SA, Spain

- Pharmaxis, Australia

- Pfizer, USA, UK, Eire & Australia

- Cipla, India

- Astellas Pharma Europe, Netherlands

- Lupin, India

Humidification & drying specialists

You may also be interested in...

Hammam, Caldarium and Rhassoul

Steam baths

Outdoor mist cooling systems

Dehumidifiers for ice prevention in cold store and freezers

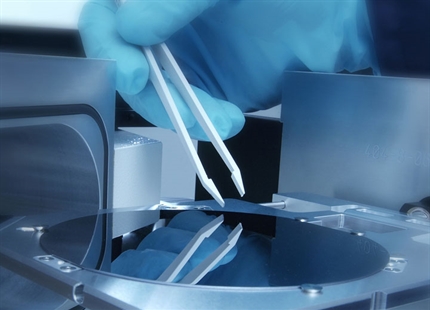

Humidification & humidity control in semiconductor & PCB manufacturing

Insectary & insect breeding

Lithium ion battery production

Drying Rooms

Swimming pool dehumidification