Eliminating static with humidification & humidity control

Humidification is a very effective way to eliminate the build-up of static electricity in manufacturing environments. By keeping the humidity at 55%RH the moisture content of the air is a natural conductor and earths any potential static charge.

Static build-up in manufacturing environments often causes a reduction in productivity, a drop in product quality, safety issues with uncontrolled sparks, and physical damage to equipment, especially electronics and PCBs.

These static problems are particularly prevalent in industries like packaging, printing, paper, plastics, textiles, electronics, automotive manufacturing and pharmaceuticals.

In order for friction to produce a static charge the air must be below 45%RH. Between 45-55%RH static will still build-up but at a reduced level as it leaks to ground through the moisture content of the air. Keeping the air at above 55%RH ensures static never builds-up.

For large environments like printing halls or manufacturing lines, direct room humidifiers present an effective and economical solution. Atomising nozzles are mounted in the ceiling space and release a fine spray which raises the humidity to the required level.

However, industrial machines that generate heat can encourage static by creating their own dry micro-climates. Heat dries the air so a room with an overall humidity of 60%RH at 18°C may have localised dry air pockets by hot machines of less than 45%RH. If this machine also produces the friction required for static build-up, then there is a potential risk of static problems.

Where this is the case, localised spray systems can be employed to raise the humidity in the local area. Individual nozzles located directly on machines can ensure temperature gains don’t encourage dry air and therefore static build-up.

Benefits of Condair humidification for static elimination:

- Extensive experience around the world in many manufacturing industries

- Comprehensive product range to precisely meet each project's requirements

- Increased production efficiencies and reduced machine downtime

- Low energy humidification systems with low operating costs

- Low maintenance solutions to reduce on-going service requirements

- Comprehensive service of advice, design, supply, installation, commissioning, maintenance and spares supply

Other industries where Condair delivers vital humidity control

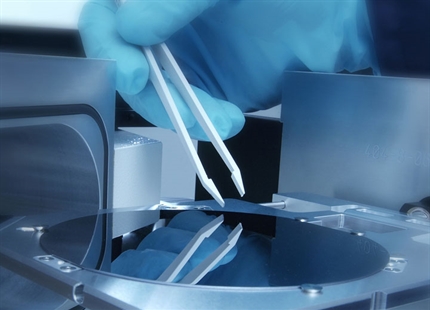

Humidification & humidity control in semiconductor & PCB manufacturing

Preventing static electricity and dimensional changes from occurring on the surface of the silicon ...

Read moreInsectary & insect breeding

Breeding of insects for zoology, research or to contribute protein to the food chain, requires spec...

Read moreExplosive & munition manufacturing humidification

Prevention of electro static risk to combustible materials.

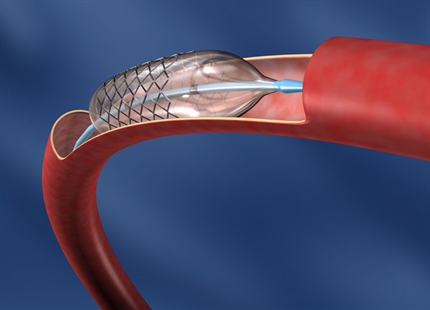

Read moreMedical device manufacturing humidification

Improves yields and reduces waste.

Read morePaper & pulp production humidification

Prevents dimensional changes.

Read morePharmaceutical manufacturing humidification

Increases efficiency & yields.

Read morePrinting humidification

Prevents dimensional change and improves production processes.

Read moreTextile manufacturing humidification

For improved yield & quality.

Read moreTobacco production humidification

Improved product quality and production efficiency.

Read moreSpray booth humidification

Prevents evaporation of water-based paints and improves finish.

Read more